Imagine effortlessly bending intricate shapes into metal, transforming raw materials into elegant creations. This is the power of the 3-in-1 Tubing Bender—a tool that empowers professionals and DIY enthusiasts alike to tackle complex projects with unparalleled precision and ease. Whether you’re a homeowner undertaking a plumbing repair, an artist crafting a unique metal sculpture, or an HVAC technician installing a sophisticated system, the 3-in-1 Tubing Bender is your key to success.

The Anatomy of Precision: Engineered for Excellence

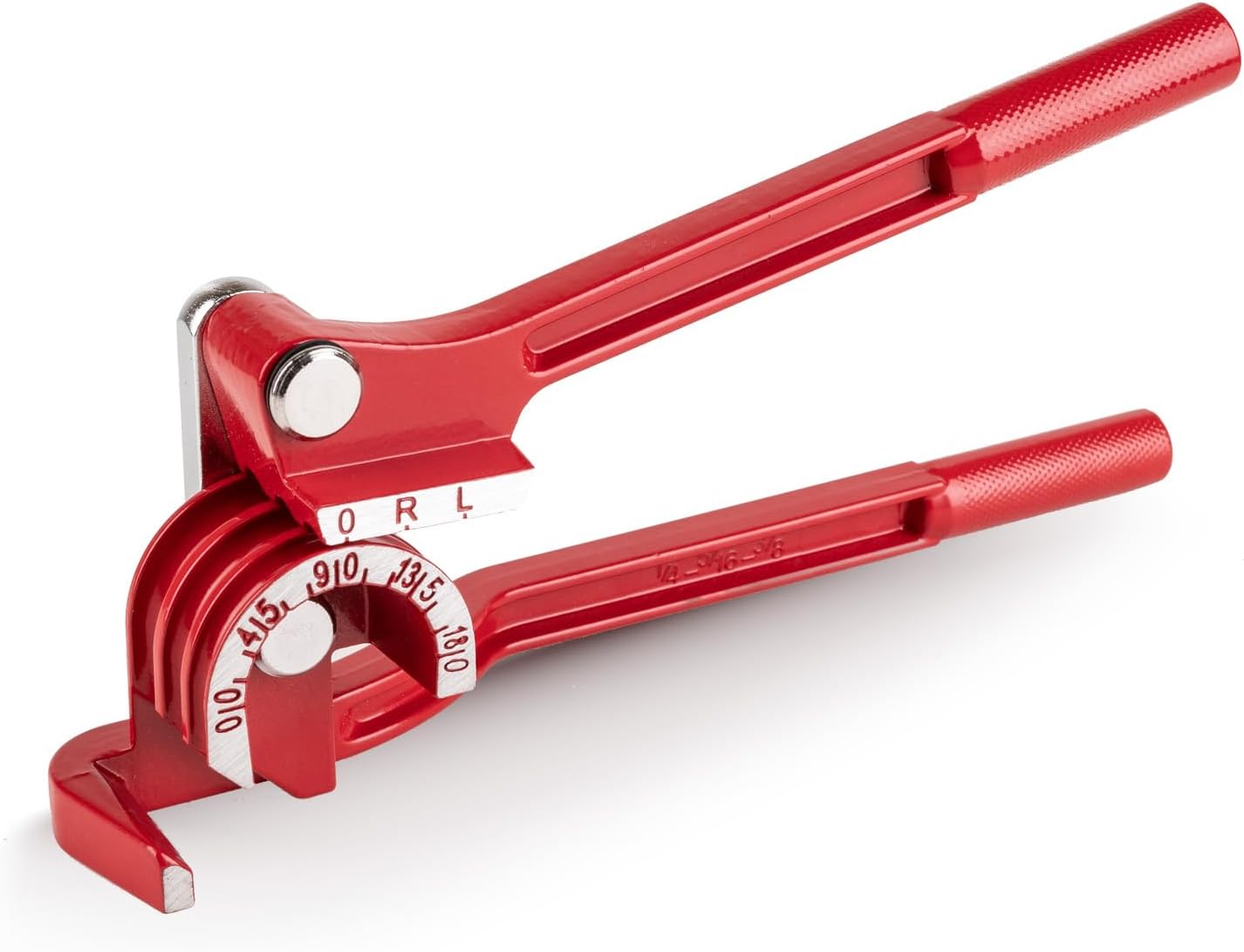

At the heart of the 3 in 1 Tubing Bender lies its ingenious design, which incorporates three distinct groove sizes to accommodate tubes with outer diameters of 1/4″, 5/16″, and 3/8″. These carefully engineered grooves, crafted to meet the highest standards of quality and precision, provide a snug and secure fit for each tube size. The result? A seamless workflow that allows you to switch between sizes quickly and easily, without the need for multiple tools.

But the precision doesn’t end there. The 3 in 1 Tubing Bender boasts an impressive bending range of 0 to 180 degrees, giving you unparalleled control over the shape and angle of your bends. Whether you need a gentle curve or a sharp 90-degree turn, this tool delivers with unwavering accuracy. The secret lies in its robust construction and thoughtful design, which ensures that every bend is executed with the utmost precision.

The Strength of Aluminum: Lightweight, Durable, and Rust-Resistant

SYIZYEN 3 In 1 Tubing Bender

This pipe bender tool is suitable for three OD sizes of 1/4, 5/16 and 3/8 inch, it can bend copper, aluminum, brass and thin stainless steel tubes from 0-180 degrees, and we can adjust the angle of the tube bending as we need. This tube bender is made of high-precision aluminum, with sturdy frame construction and smooth coated exterior, this tool have a long service life.

When it comes to tube bending, the choice of material is crucial. That’s why the 3 in one Tubing Bender is crafted from high-precision aluminum—a material that offers a perfect balance of strength, durability, and lightweight handling. Unlike steel, which can be heavy and prone to rust, aluminum provides a robust yet manageable solution. Its inherent resistance to corrosion ensures that your bender will withstand the test of time, even in demanding environments.

But the advantages of aluminum don’t stop there. Compared to plastic, which lacks the necessary rigidity and strength, aluminum ensures precise and consistent bends every time. When you apply pressure to the bender’s handle, the aluminum body distributes the force evenly along the tube, minimizing the risk of kinking or deformation. This is particularly crucial when working with softer metals like copper, where even the slightest irregularity can compromise the integrity of the tube.

Ergonomics in Action: Comfort and Control in Perfect Harmony

Tube bending can be a physically demanding task, especially when working in confined spaces or tackling large-scale projects. The three in one Tubing Bender addresses this challenge head-on with its ergonomically designed non-slip knurled grip. This thoughtful feature not only provides a secure and comfortable hold but also reduces strain and fatigue during extended use. The result? Improved precision and control, even in the most challenging situations.

But comfort alone is not enough. To achieve precise bends consistently, you need a tool that offers stability and control. That’s where the bender’s integrated fixing hooks come into play. These strategically placed hooks securely hold the tube in place during the bending process, preventing slippage and ensuring accurate and repeatable bends. Whether you’re working with challenging angles or materials, the three in one Tubing Bender provides the stability and control you need to achieve professional-grade results.

Mastering the Art of Bending: A Step-by-Step Guide

Using the 3-in-1 Tubing Bender is a skill that can be mastered with practice and attention to detail. To help you achieve perfect bends every time, follow these step-by-step instructions:

- Preparation: Select the appropriate groove size for your tube’s outer diameter and apply a suitable lubricant to the tube’s surface to reduce friction and prevent scratches.

- Secure the Tube: Place the tube into the corresponding groove, ensuring a snug fit, and engage the fixing hooks to hold it firmly in place.

- Apply Pressure: Grasp the bender’s ergonomic handle and apply steady, even pressure. The aluminum construction helps distribute the force evenly, preventing kinks or flat spots.

- Achieve the Perfect Angle: As you apply pressure, closely monitor the angle of your bend. The 3-in-1 Tubing Bender’s precision markings allow you to achieve angles ranging from 0 to 180 degrees with ease.

- Finalize: Once you’ve reached the desired angle, carefully remove the tube from the bender and inspect your work for any signs of deformation or unevenness.

Pro Tip: When bending softer metals like copper, take your time and apply pressure slowly to ensure a smooth, perfect curve. Rushing the process can lead to uneven or kinked bends.

Unleashing Creativity: Versatility Across Industries

The 3-in-1 Tubing Bender is not just a tool; it’s a catalyst for creativity across a wide range of industries and applications. Let’s explore some of the ways in which this versatile tool can transform your projects:

- HVAC Excellence: For HVAC technicians, precision is paramount when installing or repairing refrigerant lines. The 3-in-1 Tubing Bender excels in creating clean, kink-free bends in copper tubing, ensuring optimal system performance and longevity.

- Automotive Artistry: In the world of automotive restoration and customization, the 3-in-1 Tubing Bender is a game-changer. From crafting custom brake lines to fabricating unique exhaust systems, this tool allows mechanics and enthusiasts to bring their vision to life with unparalleled precision.

- Plumbing Perfection: Plumbing projects often require intricate bends and tight angles, especially in confined spaces. With the 3-in-1 Tubing Bender, plumbers can navigate these challenges with ease, creating precise and reliable connections that stand the test of time.

- Artistic Expression: For artists working with metal, the 3-in-1 Tubing Bender opens up a world of creative possibilities. Imagine crafting a stunning sculpture with elegantly curved metal tubes or designing a one-of-a-kind furniture piece with intricate tubular elements. With this tool, the only limit is your imagination.

The 3-in-1 Tubing Bender: A Cut Above the Rest

When it comes to choosing the right tube bending tool, it’s essential to consider how the 3-in-1 Tubing Bender stacks up against the competition. Let’s take a closer look at the key features that set this tool apart:

| Feature | 3-in-1 Tubing Bender | Competitor A | Competitor B |

| Tube Sizes | 1/4″, 5/16″, 3/8″ | 1/4″ only | 3/8″ only |

| Bending Angle Range | 0 to 180 degrees | 0 to 90 degrees | 0 to 120 degrees |

| Material | High-precision aluminum | Plastic | Steel |

| Ergonomic Grip | Non-slip knurled grip | Basic grip | No grip |

| Fixing Hooks | Integrated | Not available | Not available |

| Precision Markings | Clear and easy to read | Limited | Hard to read |

| Maximum Torque | 50 ft-lbs | 20 ft-lbs | 60 ft-lbs |

As you can see, the 3-in-1 Tubing Bender outshines its competitors in several key areas. Its ability to accommodate multiple tube sizes eliminates the need for multiple tools, saving you time and money. The high-precision aluminum construction ensures durability and precision, while the ergonomic grip and integrated fixing hooks provide unparalleled control and comfort during use.

While Competitor B boasts a higher maximum torque, the 3-in-1 Tubing Bender’s 50 ft-lbs capacity is more than sufficient for most bending applications. Moreover, the 3-in-1 Tubing Bender’s clear and easy-to-read precision markings make it a breeze to achieve accurate angles, whereas Competitor A’s limited markings and Competitor B’s hard-to-read scale can lead to frustration and errors.

In summary, the 3-in-1 Tubing Bender stands out as the most versatile, durable, and user-friendly option on the market. Its superior design and engineering make it the go-to choice for professionals and DIY enthusiasts who demand the best.

Elevating Your Bending Game: Expert Tips and Troubleshooting

To truly master the art of tube bending, consider these expert tips and troubleshooting techniques:

- Lubrication Matters: Always apply a suitable lubricant to your tube before bending to reduce friction, prevent scratches, and ensure a smoother bending process. Experiment with different lubricants to find the one that works best for your specific material and application.

- Slow and Steady: Rushing through a bend can lead to kinks, flat spots, or uneven angles. Take your time and apply pressure gradually and consistently to achieve the perfect bend.

- Practice Makes Perfect: Like any skill, tube bending requires practice to master. Familiarize yourself with the 3-in-1 Tubing Bender’s features and experiment with different angles and materials. As you gain experience, you’ll develop a feel for the tool and be able to execute precise bends with confidence.

- Troubleshooting Common Issues:

- Over-bending: If you’ve bent the tube too far, carefully apply pressure in the opposite direction to straighten it slightly. Use the precision markings to guide you back to the desired angle.

- Uneven bends: If your bend is uneven or asymmetrical, check that the tube is properly secured in the groove and that you’re applying pressure evenly. Practice on scrap pieces to perfect your technique.

- Kinks or flat spots often occur when you rush the bending process or apply too much pressure too quickly. Take time and gradually apply pressure to maintain the tube’s round shape.

- Maintenance Matters: To keep your 3-in-1 Tubing Bender in top condition, regularly clean the tool and lubricate the moving parts, such as the fixing hooks and the pivot point. Inspect the grooves for any signs of wear or damage, and store the tool in a dry, protected place when not in use.

Conclusion: Precision, Versatility, and Durability in One Tool

The 3-in-1 Tubing Bender is more than just a tool; it’s an investment in your craft. Whether you’re a professional tradesman or a passionate DIY enthusiast, this bender empowers you to tackle any project with confidence and precision. Its versatile design, durable construction, and user-friendly features make it the ultimate choice for anyone who demands the best.

Read More From Us

- ICOOL 5pcs Spring Tubing Benders Set Review

- Power Through Rebar Cutting Jobs: Happybuy Electric Rebar Cutter Review

- Discover the Power and Precision of the Dremel 9904 Rotary Tool Bit

- ARES 10024 Tubing Bender Pliers Review: A Comprehensive Guide

- Mastering Precision Bends in Tight Spaces: The Titan Tools Mini Tubing Bender