In the world of concrete finishing, precision and durability are everything. The right tool can make all the difference in achieving professional-grade results that stand the test of time. Enter the Kraft Tool CF023 Stainless Steel Hand Seamer/Groover, a top-of-the-line choice for contractors and serious DIYers alike. This in-depth review will explore the features, benefits, and real-world performance of this exceptional tool to help you make an informed decision for your next project.

First Impressions: Quality You Can Feel

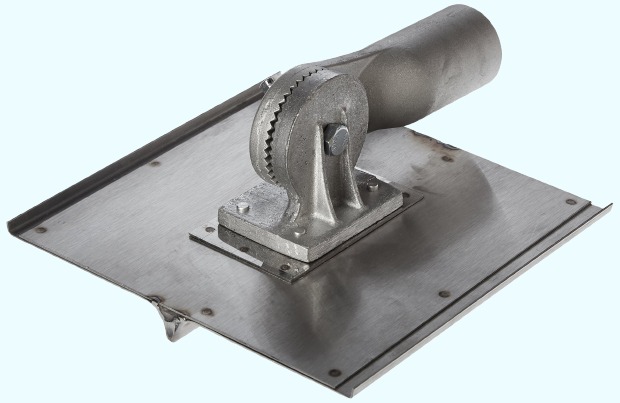

Upon unboxing the Kraft Tool CF023, the first thing you’ll notice is its sturdy, well-crafted construction. The tool feels substantial in the hand, with a comfortable heft that speaks to its quality. The stainless steel head is polished to a high sheen, free of any burrs or imperfections. The wooden handle is smoothly sanded and shaped to fit the natural contours of your grip. Even before putting it to use, it’s clear that this is a tool built for serious work.

304 Stainless Steel: The Gold Standard for Durability

Kraft Tool CF023 Stainless Steel Hand Seamer/Groover

- Country Of Origin: United States

- Model Number: CF023

- Item Package Dimension: 9.0″ L x 6.0″ W x 0.375″ H

- Item Package Weight: 1.0 lb

One of the key features setting this hand seamer apart is its premium 304 stainless steel construction. But what makes 304 stainless so special? For starters, it offers exceptional tensile strength and impact resistance, ensuring that the groover head can withstand the rigors of heavy use without bending, chipping, or deforming.

In fact, 304 stainless boasts a tensile strength of around 31.2 ksi (215 MPa) and a yield strength of 42 ksi (290 MPa) – far higher than many other common tool materials. This means that the groover will maintain its precise shape and cutting edge even when subjected to the stresses and impacts of working with high-strength concrete mixes.

But strength is only part of the equation. The 304 alloy is also highly resistant to corrosion and chemical degradation, thanks to its high chromium and nickel content. This is especially important in the world of concrete, where tools are routinely exposed to moisture, salts, and other harsh substances that can quickly degrade lesser metals.

With a 304 stainless head, the Kraft Tool CF023 is built to withstand the test of time and the elements. It will maintain its sleek, rust-free appearance and smooth cutting action year after year, even in the most demanding environmental conditions.

Ergonomic Hardwood Handle: Comfort and Control in Every Grip

Of course, durability means little if a tool is uncomfortable or unwieldy to use. That’s where the CF023’s thoughtfully designed hardwood handle comes in. Kraft Tool has opted for a premium hardwood, likely a dense, tight-grained species like oak or birch, for its superior strength, shock absorption, and long-term resilience.

The benefits of a hardwood handle are many. First and foremost, it provides a naturally comfortable and accommodating grip, thanks to its smooth, sanded surface and contoured shape. The wood warms quickly to the touch, making it a pleasure to hold even in cold weather, and its inherent texture offers a secure grip without the need for aggressive knurling or rubberization.

But comfort is only one part of the equation. A hardwood handle also excels at absorbing and dissipating the shocks and vibrations that can occur when grooving concrete, especially when working with harder, more abrasive mixes. This helps to reduce fatigue and minimize stress on the user’s hands, wrists, and arms over long work sessions.

Compare this to the hollow plastic or metal handles found on some other groovers, which can transmit much more of that jarring feedback and quickly lead to discomfort and even repetitive strain injuries with prolonged use.

In addition to its ergonomic benefits, a hardwood handle is also incredibly durable and resistant to the kinds of wear and tear that can quickly degrade other materials. Hardwoods are naturally resistant to moisture absorption, which means the handle won’t swell, warp, or crack even when exposed to wet concrete or humid conditions.

And if the handle does become damaged or degraded over time, it can be easily and affordably replaced with a new one, ensuring that the hand groover as a whole will provide reliable service for years to come.

Precision-Engineered Grooves: The Art and Science of Control Joints

At the business end of the CF023, you’ll find the precision-machined stainless steel head that gives this tool its unmatched performance. With its optimized 1/2″ radius and 3/4″ depth, this groover is designed to create control joints that effectively manage shrinkage stresses and prevent random cracking in concrete slabs of all types and sizes.

But what exactly makes these dimensions so effective? It all comes down to the fundamental principles of concrete contraction and crack control.

As concrete cures, it undergoes a process of shrinkage as excess water evaporates and the mix solidifies. This shrinkage creates internal stresses that, if left unchecked, can lead to unsightly and potentially damaging random cracks throughout the slab.

Control joints, also known as contraction joints, are intentional lines of weakness that are tooled, sawed, or molded into the surface of the concrete at regular intervals. These joints create a predetermined path for cracks to follow as the slab shrinks, concentrating the stresses along those lines and preventing them from propagating across the surface.

For control joints to be effective, they need to be the right depth and spacing for the thickness and properties of the concrete mix being used. A good rule of thumb is to make the joint depth about one-quarter to one-third the thickness of the slab, and to space the joints at intervals of about 24 to 36 times the thickness of the concrete.

With its 3/4″ depth, the Kraft Tool CF023 is ideally suited for creating control joints in slabs between 2 1/4″ and 3″ thick – a common range for many residential and light commercial applications. And its 1/2″ radius creates a smooth, rounded groove that helps to minimize the risk of joint spalling or raveling over time.

But the benefits of the CF023’s precision engineering go beyond just the numbers. The sharp, clean edges and consistent depth of its grooves also help to create a more aesthetically pleasing and professional-looking finish, whether you’re working on a basic broom-finished driveway or an intricately patterned decorative patio.

By concentrating the shrinkage stresses along those crisp, even lines, the CF023 helps to minimize the risk of unsightly surface cracks and enhances the overall durability and integrity of the slab. And because it creates those joints quickly and easily, with minimal risk of over-cutting or under-cutting, it can help to speed up the finishing process and boost productivity on the job site.

Putting the Groover to Work: Tips and Techniques from the Pros

Using the Kraft Tool CF023 is a straightforward process, but as with any tool, there are certain techniques and best practices that can help you get the most out of it. Here are some tips and insights from seasoned concrete pros on how to use this groover effectively:

Timing is Everything

One of the most critical factors in successful grooving is timing. You’ll want to wait until the concrete has set up enough to hold an edge, but not so long that it becomes too hard to groove cleanly and easily.

For most standard concrete mixes, this “sweet spot” typically falls between 1 and 4 hours after finishing, depending on factors like temperature, humidity, and mix design. A good rule of thumb is the “thumb test”: press your thumb firmly into the surface of the concrete, and if it leaves a clean imprint about 1/8″ to 1/4″ deep, you’re in the ideal grooving window.

Plan Your Groove Pattern

Before you start grooving, it’s important to have a clear plan for your control joint layout. This will depend on factors like the size and shape of the slab, the intended use of the surface, and any decorative patterns or features you want to incorporate.

As a general guideline, aim to space your joints at intervals of 24 to 36 times the thickness of the slab, and to create a roughly square or rectangular grid pattern across the surface. For example, for a 4″ thick slab, you might space your joints every 8 to 12 feet in each direction.

Use a chalk line or measuring tape to mark out your joint locations, and consider using a straightedge or grooving guide to help maintain a consistent depth and alignment as you work.

Technique Matters

When you’re ready to start grooving, grip the CF023 securely with both hands and position the head at a slight angle to the surface of the concrete. Apply firm, even pressure and draw the groover smoothly along the marked line, taking care to maintain a consistent depth and speed.

For best results, make two passes over each joint – one to establish the initial groove, and a second to fine-tune the depth and smooth out any irregularities. Avoid “sawing” the groover back and forth, as this can create a ragged or uneven edge.

If you’re working on a large slab or a complex pattern, it can be helpful to work in sections and to periodically check your joints for consistency and alignment. Use a straightedge or measuring tape to ensure that your joints are staying true to your layout lines, and make any necessary adjustments as you go.

Keep Your Groover Clean and Sharp

Over time, the stainless steel head of your groover can become clogged with concrete residue or start to lose its edge, especially if you’re working with particularly abrasive or hard mixes. To keep your groover performing at its best, it’s important to clean it regularly and to sharpen or replace the blade as needed.

To clean your groover, simply rinse it thoroughly with clean water after each use, taking care to remove any buildup of concrete paste or debris. For stubborn residue, you can use a stiff-bristled brush or a putty knife to gently scrape the head clean.

If the blade starts to become dull or nicked, you can use a fine-grit sharpening stone or diamond file to carefully hone the cutting edge back to a crisp, clean bevel. Be sure to maintain the original angle and contour of the blade, and avoid over-sharpening or creating any burrs or irregularities.

With proper maintenance and care, your Kraft Tool CF023 will provide reliable, high-quality grooving performance for years to come, job after job.

Real-World Results: Putting the CF023 to the Test

Of course, the true measure of any tool is how it performs in the hands of real users, on real job sites. To get a sense of how the CF023 stacks up, we gathered feedback from concrete professionals and DIYers who have put this groover through its paces on a wide range of projects.

Versatility on Various Mixes and Slabs

One of the most common praises for the CF023 is its versatility and adaptability to different concrete mix designs and slab types. Users report excellent results on everything from basic ready-mix to high-performance engineered mixes, and from simple broom-finished driveways to intricately patterned decorative patios.

As one experienced concrete finisher put it:

“I’ve used this groover on just about every type of mix and slab you can imagine, from lightweight to high-strength, from air-entrained to fiber-reinforced. It handles them all with ease and consistency. I don’t have to worry about changing my technique or babying the tool – it just works, every time.”

Precision and Consistency in Every Joint

Another key benefit that users consistently highlight is the CF023’s ability to create clean, precise, and consistent control joints, even in challenging conditions or on irregular surfaces. The sharp, durable blade and ergonomic handle design make it easy to maintain a straight, even groove from start to finish, with minimal wrist fatigue or strain.

One contractor shared this experience:

“We were working on a big commercial slab with a lot of odd angles and curves, and I was worried about getting the joints right. But the CF023 made it a breeze. The blade cut through the hard, fiber-reinforced mix like butter, and the handle gave me plenty of control and leverage to follow the layout lines precisely. The joints came out perfect, and the client was thrilled with the result.”

Durability and Longevity in Tough Conditions

Finally, many users praise the CF023 for its exceptional durability and long-term performance, even in harsh or abusive environments. The stainless steel head and hardwood handle can withstand years of heavy use and exposure to the elements without rusting, corroding, or losing their shape or functionality.

As one long-time user put it:

“I’ve had my CF023 for over a decade now, and it’s still going strong. I’ve used it on everything from small patch jobs to massive warehouse floors, in all kinds of weather and conditions. The stainless steel still looks like new, and the handle has held up without any cracks or splits. It’s definitely built to last.”

Caring for Your CF023: Maintenance and Storage Best Practices

To keep your Kraft Tool CF023 performing at its best for years to come, it’s important to give it a little TLC from time to time. Here are some tips and best practices for maintaining and storing your groover:

Cleaning and Drying After Each Use

After each use, be sure to rinse your groover thoroughly with clean water to remove any concrete residue or buildup. A stiff-bristled brush or putty knife can help loosen stubborn debris, but avoid using anything too abrasive that could scratch or damage the stainless steel head.

Once you’ve removed the bulk of the residue, dry the groover completely with a clean, lint-free cloth. This is especially important for preventing rust or corrosion, as even stainless steel can be susceptible to oxidation if left damp for too long.

If you’re working in a humid environment or storing the groover for an extended period, you may want to give it an extra layer of protection by applying a light coating of oil or lubricant to the head and blade. A silicone-based lubricant or even a simple household oil like WD-40 can help displace moisture and prevent rust from forming.

Storing in a Cool, Dry Place

When you’re not using your groover, it’s best to store it in a cool, dry place away from direct sunlight or extreme temperatures. A sturdy toolbox or storage cabinet is ideal, but even a simple shelf or drawer will do as long as it’s clean and moisture-free.

Avoid storing your groover in damp or humid areas like basements or sheds, as this can promote rust and corrosion over time. If you must store it in a less-than-ideal environment, consider placing it in a sealed plastic bag or container with a desiccant packet to absorb excess moisture.

Maintaining the Hardwood Handle

The hardwood handle of your CF023 is naturally resistant to moisture and wear, but it can still benefit from occasional maintenance to keep it looking and feeling its best. Every few months, or whenever the wood starts to feel dry or rough, apply a light coating of boiled linseed oil or a similar wood-safe finish to nourish and protect the grain.

To apply the oil, simply pour a small amount onto a clean cloth and rub it into the handle, following the direction of the grain. Let the oil soak in for a few minutes, then wipe away any excess with a dry cloth. Avoid getting oil on the stainless steel head or blade, as this can attract dirt and debris. If the handle becomes damaged or worn over time, don’t worry – Kraft Tool offers replacement handles that are easy to install with just a few basic tools. Simply remove the old handle by unscrewing the retaining bolts, then attach the new handle in its place, making sure it’s snug and secure.

Frequently Asked Questions

Can the CF023 be used on green concrete?

Yes, the CF023 is an excellent choice for grooving concrete that is still in the plastic state, or “green.” In fact, this is the ideal time to groove, as the concrete is firm enough to hold the shape of the groove but still soft enough to cut easily.

Just be sure to wait until the concrete has set up enough that it doesn’t slump or sag when grooved. The thumb test described earlier is a good way to check if the concrete is ready.

How does the CF023 compare to a grooving trowel?

While a grooving trowel can be used to create joints in concrete, it has a few key limitations compared to a dedicated groover like the CF023.

First, a trowel is typically much larger and heavier than a groover, which can make it more cumbersome to maneuver and control. This is especially true when trying to cut precise, straight lines over long distances.

Second, the blade of a trowel is usually not as thick or rigid as the head of a groover. This means it may flex or wobble as you cut, resulting in uneven or wavy grooves. The stiff, precision-machined head of the CF023, by contrast, ensures straight, consistent grooves every time.

Finally, a trowel doesn’t offer the same ergonomic benefits as the CF023’s contoured wooden handle. Over long days of grooving, this can lead to increased hand fatigue and discomfort.

So while a trowel can work in a pinch, for truly professional results, a dedicated groover like the CF023 is the way to go.

Can the wooden handle be replaced if damaged?

The hardwood handle of the CF023 is designed for durability and should provide years of comfortable use with proper care. However, in the event that the handle does become damaged or degraded over time, it can be easily replaced.

Kraft Tool offers replacement handles specifically designed to fit the CF023 and other similar groovers. These handles are crafted from the same premium hardwoods as the original, such as solid oak or birch, which are selected for their strength, durability, and resistance to moisture.

The replacement handles are carefully shaped and contoured to match the ergonomic profile of the original, ensuring a comfortable, secure grip that reduces fatigue and enhances control. They are also pre-drilled for easy installation, with hole placements that precisely align with the bolt pattern on the groover head.

To ensure a seamless fit and optimal performance, Kraft Tool subjects each replacement handle to rigorous quality control standards. This includes inspecting the wood grain for consistency and integrity, verifying the dimensional accuracy of the drill holes, and testing the handle’s fit and finish on actual groover heads.

The result is a replacement handle that not only looks and feels like the original, but also delivers the same high level of comfort, control, and durability that users expect from the CF023. With the ability to easily swap out the handle as needed, concrete pros can maintain their tool in top condition and extend its useful life even further.

It’s worth noting that while some other brands also offer replacement handles for their groovers, the quality and attention to detail can vary widely. Some may use lower-grade wood or less precise manufacturing techniques, resulting in a handle that feels rough, ill-fitting, or prone to cracking and splintering over time.

With Kraft Tool’s genuine replacement handles, however, users can trust that they are getting a product that is built to the same exacting standards as the original CF023 itself. This commitment to quality and consistency is just one more reason why this tool is a top choice among discerning concrete professionals.

So whether you’re replacing a damaged handle or simply want a fresh grip for your trusty groover, Kraft Tool’s replacement handles are the way to go. With their premium materials, precision craftsmanship, and perfect fit, they’ll help keep your CF023 in top form for years to come.

To replace the handle, simply remove the old handle by unscrewing the bolts that secure it to the head of the groover. Then, align the new handle with the bolt holes and secure it in place with the included hardware. The whole process takes just a few minutes and requires only basic hand tools. With the ability to replace the handle as needed, you can be confident that your CF023 will provide a lifetime of reliable service.

The Bottom Line

When it comes down to it, choosing the right hand groover is all about finding the best balance of performance, durability, and comfort for your needs. And in all of these areas, the Kraft Tool CF023 is tough to beat.

With its precision-machined stainless steel head, ergonomic hardwood handle, and versatile grooving capabilities, this tool is designed from the ground up for serious concrete professionals. Whether you’re a seasoned contractor or a dedicated DIYer, the CF023 has the chops to tackle even the most demanding grooving jobs with ease.

But perhaps the most compelling reason to choose the CF023 is the confidence it inspires every time you pick it up. From the moment you feel the solid heft of the stainless steel head and the comfortable contours of the wooden handle, you know this is a tool you can rely on, job after job, year after year.

So if you’re ready to step up your grooving game and invest in a tool that won’t let you down, look no further than the Kraft Tool CF023. With its unbeatable combination of performance, durability, and value, it’s the clear choice for discerning concrete pros who demand the very best.

Read More From Us

- Conquering Clogged Tub Drains: The Ultimate Guide to BearHut’s Drain Wrench

- Mastering Tight-Space Plumbing: A Comprehensive Guide to the LAISGOO Angle Stop Wrench Kit

- KAKA INDUSTRIAL MUB-1 Review: The Compact Metal Bender That Delivers Precision and Versatility

- Mastering Sheet Metal Work: A Comprehensive Guide to Professional Flanging Tools

- Katerk 12pc Portable Bit Holder Keychain: The Ultimate Tool Organizer