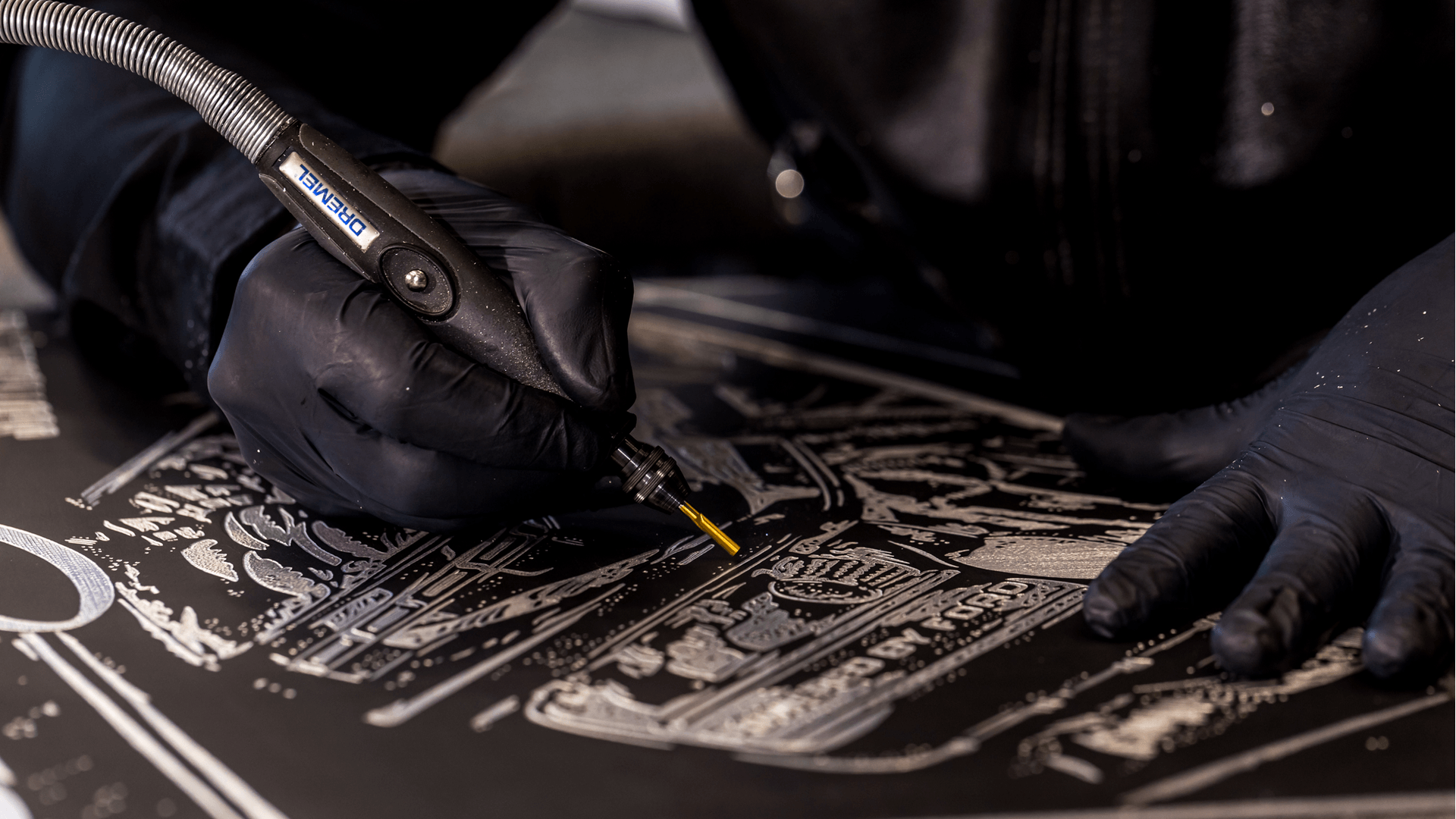

Picture this: you’re working on an intricate engraving project on a tough material like hardened steel or ceramic. You need a tool that can handle the demands of precision work without wearing down quickly. Enter the Dremel 9904 – a tungsten carbide rotary tool attachment engineered for strength, accuracy, and versatility.

This robust cutter, crafted from one of the hardest materials available, excels at intricate engraving, shaping, smoothing and material removal on a wide array of challenging substrates. Whether you’re a professional metalworker, DIY enthusiast, jewelry maker, or craft artist, the Dremel 9904 offers a compelling blend of power and finesse to elevate your projects.

In this comprehensive guide, we’ll explore the features, benefits, and applications of this remarkable tool. We’ll dive into its technical specifications, provide tips for optimal use, and hear from real users about their experiences. By the end, you’ll have a clear understanding of how the Dremel 9904 can transform your work on hard materials. Let’s jump in!

Product Overview

Dremel 9904 Tungsten Carbide Cutter

- Dremel highly-durable tungsten carbide carving bits can be used for more aggressive applications to shape, smooth, or grind hard materials such as metals, hardened steel, fire ceramics, cast iron, plastics and hard woods.

- Ideal for projects like metal or glass engraving, stone carving, or removing flash from castings.

- Use higher speeds for hard woods, slower speeds for metals and very slow speeds for plastics

- What’s Included: 3/32″ Tungsten Carbide Carving Bit (x1)

- For use with rotary tools that can accommodate a 1/8″ shank size

At first glance, the Dremel 9904 might seem like just another small rotary tool bit. But a closer look reveals its superior construction and capabilities. This 3/32″ diameter cutter, weighing only 0.3 ounces, packs an outsized punch when it comes to tough materials.

The magic is in the materials. Unlike many other bits made from steel or carbide, the Dremel 9904 is crafted from tungsten carbide. This extremely hard substance, ranking a 9 on the Mohs hardness scale, enables the cutter to maintain a sharp edge and precise shape even under the stresses of high-speed use on hard materials.

The Dremel 9904’s construction makes it remarkably durable and resistant to wear, allowing it to power through materials that would quickly dull or damage other bits. This longevity means you can work more efficiently, spending less time swapping out worn-down attachments.

So what materials can the 9904 handle? The list covers an impressive range:

| Compatible Materials |

| Glass |

| Ceramics |

| Hardened Steel |

| Stainless Steel |

| Cast Iron |

| Non-ferrous Metals |

| Stone |

| Hardwoods |

| Plastics |

This versatility makes the Dremel 9904 a go-to choice for a wide variety of projects, from home repairs to jewelry making to artistic pursuits.

Key Features & Technical Specifications

Let’s take a closer look at the key features that set the Dremel 9904 apart:

Superior Material: Tungsten Carbide

As we touched on earlier, the Dremel 9904’s tungsten carbide construction is a standout feature. But what exactly makes this material so special?

Tungsten carbide is a chemical compound containing equal parts tungsten and carbon atoms. The resulting crystalline material is extremely hard and dense, with a melting point of 2870°C. These properties make it exceptionally durable and resistant to wear, able to withstand the high stresses of grinding and cutting hard materials.

On the Mohs scale of mineral hardness, tungsten carbide ranks an impressive 9 out of 10. For comparison, steel measures around 4-4.5, making tungsten carbide significantly more durable. Substances like hardened steel and cast iron are no match for its strength.

The 9904’s robust tungsten carbide build allows it to maintain a sharp, precise edge much longer than bits made from softer materials. This means more efficient performance and less time lost to replacing dull or broken bits mid-project.

Optimized Geometry for Precision and Efficiency

In addition to its hard-wearing material, the Dremel 9904 boasts a unique design optimized for precision and efficient material removal. Its sharp, pointed tip enables clean, accurate cuts and intricate detailing work. Meanwhile, the tapered, angled sides excel at controlled shaping and smoothing.

This geometry works in tandem with the tungsten carbide construction to enable fast, effective grinding and engraving without sacrificing precision. The 9904 can quickly remove material while maintaining crisp edges and fine details.

Versatile Compatibility and Applications

From glass to metal to wood, the Dremel 9904’s versatility is one of its greatest assets. This rotary tool bit is compatible with a wide array of hard and soft materials, making it adaptable to countless applications.

| Material | Optimal Uses | Speed (RPM) |

| Hardwoods | Engraving, carving, shaping | High (28,000+) |

| Steel & Stainless Steel | Engraving, grinding, polishing | Medium (15,000-20,000) |

| Ceramics & Glass | Engraving, etching, shaping | Medium (15,000-20,000) |

| Plastics | Engraving, shaping (avoid heat buildup!) | Low (5,000-10,000) |

| Cast Iron | Grinding, shaping | Medium (15,000-20,000) |

Of course, achieving the best results requires tailoring your technique to the material at hand. Harder materials like steel and ceramics demand a slower, more controlled approach to prevent overheating or chipping. Softer substances like plastic require lower speeds to avoid melting.

By understanding your material’s properties and adjusting your methods accordingly, you can harness the Dremel 9904’s impressive versatility for professional-grade results across a spectrum of projects.

Benefits and Real-World Applications

With its robust construction and efficient precision, the Dremel 9904 opens up new possibilities for detail work on hard materials. Let’s explore some of its key benefits and real-life use cases.

Unmatched Durability for Demanding Projects

One of the 9904’s greatest advantages is its sheer durability. Courtesy of its tungsten carbide build, this rotary tool bit can tackle tough materials and long work sessions without wearing down or losing its edge.

Real-world example:

User CMH put the 9904 to the test removing a 1-inch wide strip of hardened steel from a tight space. After an hour of demanding work, CMH reported that the bit showed very little wear, declaring: “Totally impressed.”

For professionals and hobbyists who work with challenging materials like hardened steel or cast iron, the Dremel 9904’s staying power is a game-changer. It means less time and money spent replacing bits and more time focused on the task at hand.

Precision and Control for Intricate Details

In addition to its strength, the Dremel 9904 excels at fine detail work. Its sharp tip and tapered sides enable clean lines, precise shaping, and intricate engraving, even on tricky materials.

Real-world example:

User Chad T., who relies on the 9904 for engraving fine details into metal, praised its precision and consistency: “I have used this bit many times to do fine detail engraving in metal. It works great and lasts a long time.”

For jewelers, machinists, woodworkers and other artisans who demand accuracy and crisp details, the Dremel 9904’s precision is indispensable. Its knack for controlled material removal and fine lines opens up creative possibilities across mediums.

Versatility Across Materials and Applications

As we’ve explored, the Dremel 9904’s versatility is one of its standout features. Compatible with a broad array of materials, this rotary tool bit adapts readily to diverse applications.

Real-world examples abound:

1. Modification and shaping: User T. Park employed the 9904 to modify a metal door lock, taking advantage of its efficient cutting abilities in tight spaces.

2. Artwork and creativity: Glass engravers and stone carvers turn to the 9904 to achieve fine details and smooth finishes on unforgiving materials.

3. Hobby and home projects: DIY enthusiasts rely on the 9904 for everything from polishing cast iron machine parts to engraving personalized designs on hardwood.

No matter your material or project, the Dremel 9904 offers the flexibility and performance to see you through. Its adaptability makes it an essential part of any well-rounded toolkit.

Getting the Most from Your Dremel 9904

To harness the full potential of the Dremel 9904 and achieve optimal results, it’s important to use proper techniques and take necessary precautions. Let’s walk through some key tips.

Choosing the Right Rotary Tool and Speed

While the Dremel 9904 is compatible with a variety of rotary tools, some pairings work better than others. For best results, use a high-quality, variable speed tool that can maintain consistent RPMs under load.

Dremel’s own 4000 and 4300 high-performance rotary tools are excellently suited to the 9904, offering ample power and speed control. Aim for a tool that can sustain speeds up to 35,000 RPM to fully utilize the 9904’s capabilities.

As for speed selection, let the demands of your material be your guide:

- Harder materials like steel, glass, and ceramics call for moderate speeds around 15,000-20,000 RPM for controlled, steady cutting. Too high a speed risks overheating and tool damage.

- Softer substances like plastics require slower speeds (5,000-10,000 RPM) to prevent melting from friction-generated heat.

- Woods land in the middle, with ideal speeds depending on hardness. Harder varieties like oak fare well at high speeds (28,000+ RPM), while softer woods call for more moderate velocities.

When in doubt, start slow and gradually increase speed until you find the sweet spot for smooth, efficient cutting.

Proper Positioning and Material Securement

Careful bit positioning and proper workpiece securement are essential for making precise, controlled cuts with the Dremel 9904.

First, ensure your material is firmly secured to prevent shifting or vibration. A stable vise or clamp system works well for most projects. Attempting to cut an unsecured workpiece invites inaccuracy and potential injury.

When operating the tool, aim to maintain a low, consistent angle between bit and material, around 10-20 degrees. Avoid the temptation to press straight down with the tip, as this can cause the bit to “walk” or skip, marring your workpiece.

Instead, use smooth, steady strokes, and let the bit’s sharp tungsten carbide edges do the work. Applying too much pressure can cause overheating and premature wear. If you encounter resistance, withdraw the bit and let it cool briefly before proceeding with a lighter touch.

For optimal control and accuracy, grip your rotary tool in whatever manner feels most stable and comfortable. Some users prefer a pencil grip for detail work, while others favor a golf grip for broader strokes. Experiment to find what works best for you.

Dust and Swarf Management

The process of cutting and engraving hard materials like metal, glass, and ceramics generates a substantial amount of fine dust and cuttings (swarf). Effectively managing this debris is important for both your health and your tool’s longevity.

Always wear proper PPE including safety glasses and a dust mask or respirator, especially when working with materials like cast iron that can generate hazardous particulates. Your lungs will thank you!

In addition to protecting yourself, it’s a good idea to use a shop vacuum or dust collection system to gather the dust and swarf produced by the Dremel 9904. This not only keeps your workspace cleaner, but also prevents debris buildup from hindering the bit’s cutting action.

For metallic swarf, a strong magnet can help collect the shavings for easy disposal. Just be sure to clean your tools thoroughly after use to prevent bits of dust or metal from interfering with future operation. A quick scrub with a wire brush and some compressed air usually does the trick.

By taking the time to properly position your workpiece, select the appropriate speed, and manage dust and debris, you’ll set yourself up for success with the Dremel 9904.

Real-World Results: User Experiences

While technical specs and best practices are important, there’s no substitute for real-world experience. Let’s take a closer look at what actual users have to say about putting the Dremel 9904 through its paces.

Efficient Steel Removal in Tight Spaces

One of the most compelling user stories comes from reviewer CMH, who faced a daunting task: removing a full inch of hardened steel from a confined area. Initially unsure if the 9904 was up to the challenge, CMH was in for a pleasant surprise:

“An hour later I had all the metal removed and the cutter showed very little wear. Totally impressed.”

This anecdote perfectly encapsulates the Dremel 9904’s core strengths. Its hardy tungsten carbide construction and aggressive cutting action make quick work of even the most stubborn materials, without sacrificing longevity or precision.

For professionals and hobbyists who frequently work in tight spaces or on tough metal removal jobs, the Dremel 9904 is a reliable tool that can power through tasks that might stymie other bits.

Consistent Results for Detailed Engraving

Precision and consistency are paramount for creating intricate designs, and user Chad T. reports that the Dremel 9904 delivers both in spades. Employing this rotary tool bit for detailed metal engraving, Chad shares:

“I have used this bit many times to do fine detail engraving in metal. It works great and lasts a long time.”

This praise speaks to the 9904’s ability to maintain a clean, sharp edge through repeated use, a benefit of its durable tungsten carbide construction. For jewelers, machinists, woodworkers, and other detail-oriented craftspeople, a tool that can hold up to extensive precision work is invaluable.

By delivering crisp lines and clean material removal in a long-lasting package, the Dremel 9904 has become a go-to choice for professionals who demand reliable results in their fine engraving work.

Versatility from the Workshop to the Garage

Reviewer T. Park’s experience highlights the Dremel 9904’s impressive versatility. This user successfully employed the 9904 to modify a metal door lock, leveraging the bit’s efficient cutting abilities to complete the job in a confined space.

This is just one example of the many applications to which the Dremel 9904 is suited. Its compatibility with a wide range of materials, from glass to plastics to hardwoods, makes it adaptable to countless projects.

DIY enthusiasts appreciate the 9904’s flexibility for home repair tasks, hobbyists rely on it for everything from craft projects to automotive work, and professional artisans employ it to create stunning engraved and carved designs.

No matter your niche, chances are the Dremel 9904 has something to offer. Its versatility and consistent performance have made it a staple in workshops, studios, and garages around the world.

Comparative Analysis: The Dremel 9904 vs. Other Rotary Tool Bits

While the Dremel 9904 is undeniably a standout performer, it’s important to understand how it compares to other rotary tool bits in its class. Let’s examine how the 9904 stacks up against some popular alternatives.

Dremel 9904 vs. High-Speed Cutter (HSS) Bits

High-speed steel (HSS) bits like the Dremel 191 and 194 are commonly used for cutting and shaping wood, plastics, and soft metals. While they offer good durability and cutting speed for these materials, they can’t match the 9904’s performance on harder substrates.

| Material | Dremel 9904 Tungsten Carbide | HSS Bits (191, 194) |

| Hardened Steel | ✓ Excellent | ✕ Not recommended |

| Cast Iron | ✓ Excellent | ✕ Not recommended |

| Stainless Steel | ✓ Very Good | ~ Fair |

| Wood (hard & soft) | ✓ Very Good | ✓ Very Good |

| Plastics | ~ Good (avoid heat) | ✓ Very Good |

| Aluminum & Soft Metals | ~ Good | ✓ Excellent |

As this comparison illustrates, the Dremel 9904’s tungsten carbide construction gives it a clear advantage over HSS bits when working with hard metals like steel and cast iron. The 9904 can efficiently cut and shape these challenging materials, while HSS bits are more prone to dulling and damage under such conditions.

That said, HSS bits still have their place, particularly for users who primarily work with softer materials. The Dremel 191 and 194 bits offer excellent performance on wood, plastics, and soft metals at a generally lower price point than tungsten carbide options.

For most users, having both a Dremel 9904 and a set of HSS bits in their toolkit covers the best of both worlds: the 9904 for tougher materials and detail work, and HSS bits for general-purpose cutting and shaping of softer substrates.

Dremel 9904 vs. Silicon Carbide Grinding Stone Bits

Another common rotary tool bit category is silicon carbide grinding stones, which are designed for shaping, sharpening, and removing material from hard substrates. While these bits share some similarities with the Dremel 9904, there are key differences to consider.

| Feature | Dremel 9904 Tungsten Carbide | Silicon Carbide Grinding Stones |

| Primary Function | Cutting, engraving, shaping | Grinding, sharpening, shaping |

| Grain Structure | Fine, uniform | Coarse to fine, depending on grit |

| Edge Retention | ✓ Excellent | ~ Good |

| Precision | ✓ Excellent | ~ Good |

| Material Removal Speed | ✓ Very Good | ~ Good |

| Heat Generation | ✓ Low | ~ Moderate |

Silicon carbide grinding stones, like the Dremel 85422 and 85602, are highly effective at tasks like sharpening tools, removing burrs, and shaping hard materials. They’re available in a range of grits from coarse to fine, making them adaptable to different stages of material removal.

However, the Dremel 9904 has several advantages over silicon carbide stones. Its fine, uniform grain structure and sharp cutting edges allow for more precise, controlled material removal with less heat generation. This makes the 9904 better suited for tasks that require fine details or a high degree of accuracy.

The 9904 also boasts superior edge retention thanks to its durable tungsten carbide construction. While silicon carbide stones can wear down and lose their shape over time, the 9904 maintains its crisp edges and precise geometry for longer.

Ultimately, both tungsten carbide bits like the 9904 and silicon carbide grinding stones have their place in a well-equipped rotary tool arsenal. The 9904 excels at precise cutting, engraving, and shaping, while silicon carbide stones are ideal for grinding, sharpening, and general material removal.

Maximizing the Dremel 9904’s Potential: A Buyer’s Guide

If you’re considering adding the Dremel 9904 to your toolkit, there are a few key factors to keep in mind to ensure you get the most out of this powerful accessory. Let’s walk through some important considerations.

Pairing with the Right Rotary Tool

To fully harness the Dremel 9904’s capabilities, it’s essential to pair it with a rotary tool that can keep up. Look for a variable-speed tool with a robust motor and a speed range that can reach at least 30,000 RPM.

Dremel’s own 4000 and 4300 series rotary tools are excellent companions for the 9904, offering ample power and precise speed control. These high-performance tools provide the torque and RPM consistency necessary to let the 9904 shine, especially on demanding materials.

Investing in Quality Accessories

In addition to a capable rotary tool, it’s worth investing in quality accessories to support your work with the Dremel 9904. A sturdy vise or clamping system is crucial for holding your workpiece steady during precise cuts and engravings.

For detailed work, a flex shaft attachment can be a game-changer, allowing you to hold and maneuver the 9904 like a pencil for maximum control. And if you frequently work on intricate projects, a magnifying lamp or workbench magnifier can help you see fine details and ensure accuracy.

Proper Care and Maintenance

To get the most mileage out of your Dremel 9904, it’s important to care for it properly. Always clean the bit after each use, removing any dust, debris, or material residue that could interfere with its cutting action.

For stubborn buildup, a brass wire brush or cleaning compound can help restore the 9904’s surfaces without damaging the tungsten carbide. Be sure to store the bit in a protective case or tool roll to prevent chips or dings that could affect its precision.

With occasional re-sharpening or honing using a diamond wheel or ceramic stick, your Dremel 9904 can maintain its crisp cutting edges and peak performance for countless projects to come.

Unleashing Your Creativity with the Dremel 9904

Armed with the knowledge and techniques we’ve explored in this guide, you’re well-equipped to put the Dremel 9904’s impressive capabilities to work in your own projects. Whether you’re a seasoned pro looking to up your game or a passionate hobbyist eager to expand your creative horizons, this powerhouse accessory opens up a world of possibilities.

So why wait? Take the leap and experience the precision, efficiency, and versatility of the Dremel 9904 for yourself. With this trusty tool in your arsenal, there’s no limit to what you can create, customize, and conquer.

From intricately engraved jewelry to finely shaped mechanical components, from personalized glassware to custom-modified tools, the projects you’ll bring to life with the Dremel 9904 are bound to impress. And with each new endeavor, you’ll continue to discover new ways to harness this remarkable accessory’s potential.

In the end, the true power of the Dremel 9904 lies not just in its technical capabilities, but in the possibilities it unlocks for makers, creators, and problem-solvers like you. So go ahead – unleash your creativity, push the boundaries of what’s possible, and let the Dremel 9904 be your trusty companion on the journey.

Your next great project awaits!

Read More From Us

- ICOOL 5pcs Spring Tubing Benders Set Review

- Power Through Rebar Cutting Jobs: Happybuy Electric Rebar Cutter Review

- CARVALAX Pipe Tube Bender Set: Precision and Versatility in One Powerful Tool

- Straightening Out Your Tubing Projects: A Comprehensive Guide to the SST Pipe and Tubing Straightener

- Mastering Precision Bends in Tight Spaces: The Titan Tools Mini Tubing Bender